Return gas blower

Cryostar’s proven single stage CM type compressors are often used as return gas blowers

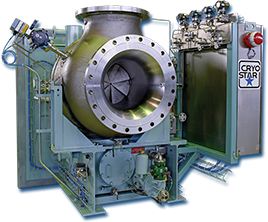

Single stage cryogenic compressor, CM series (CM200, CM300, CM400)

Electric motor driven single stage cryogenic compressor, type CM, with adjustable inlet guide vanes, complete with lube oil system, seal gas system, accessories and designed according to API617 if required (with separate lube oil system).

The whole unit is installed on a single, rigid skid. Typically this machine delivers up to 40,000 m3/h of boil-off gas with an inlet temperature of -140°C at a delivery pressure of 2.03 barA. Typical applications include cargo handling or tank maintenance.

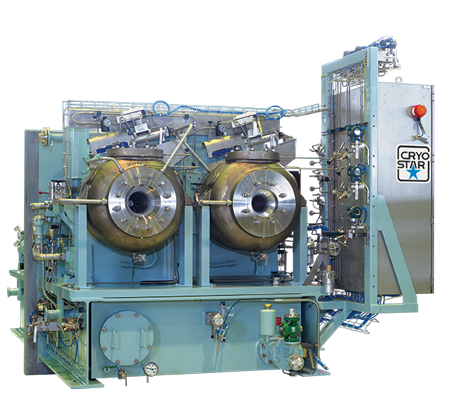

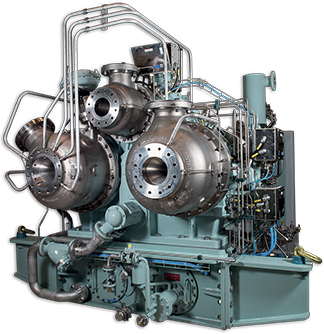

Two stage gas compressor, CM2 series (CM2-200, CM2-300)

Electric motor driven, two-stage cryogenic compressor, type 2-CM, with variable diffusor vanes, complete with lube oil system, seal gas system, accessories and designed according to API 617 if required (with separate lube oil system). Typically this machine delivers between 2,500 and 6,000 m3/h of boil-off gas with an inlet temperature of -120°C, at a delivery pressure of 6.5 barA. The whole unit is installed on a single, rigid skid. Typical applications are fuel gas supply, reliquefaction plant feed or BOG recondensing.

Electric motor driven, four-stage cryogenic/warm compressor, with variable diffusor vanes on first stage, complete with lube oil system, seal gas system, accessories and designed according to API 617 if required (with separate lube oil system).

Typically this machine delivers up to 5,500 m3/h of boil-off gas with an inlet temperature as high as -20°C, at a delivery pressure of 6.5 barA. The unit is installed on a single, rigid skid. Typical applications are fuel gas supply or BOG recondensing.

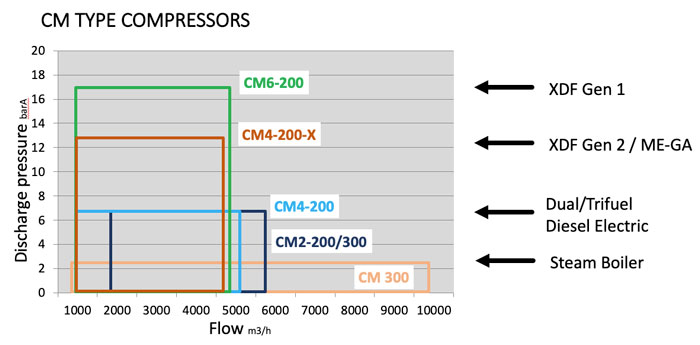

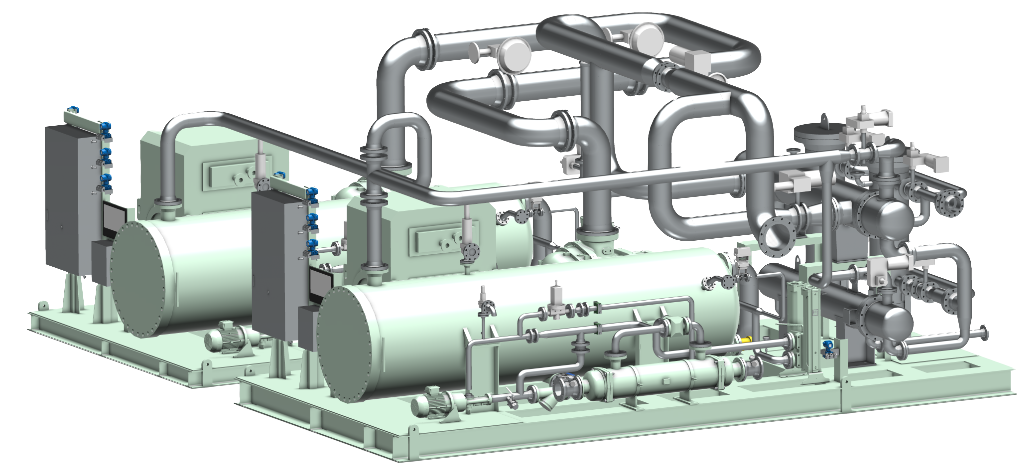

Four and six stage gas compressor, CM4 / CM6 series

Electric motor-driven multi-stage cryogenic/warm compressors equipped with variable diffuser vanes on first stage. These units are supplied with lube oil and seal gas systems, on-skid and field instruments, or to API 617 with separate lube oil system, if required.

Wide operating ranges are suitable for fuel gas feed for low pressure 2-stroke marine engines.

Typical BOG fuel gas operation ranges

6 stage BOG fuel gas compressor

SCM 360 oil-flooded screw compressor

SCM 360 oil-flooded screw compressor is a high-performance BOG screw compressor ideally suited to LNG tank pressure control and fuel gas supply on LNG carriers.

The single-stage oil-flooded compressor, utilising well-referenced technology and VFD volume control, offers a robust solution for marine fuel gas applications.

The unit is offered in a packaged skid incorporating all the oil injection system, oil removal and aftercooler required for normal operation.