The efficiency of cryogenic processes is dramatically increased when they integrate a turboexpander for generating

cold, as the isentropic efficiency of these turbines is very high. Today, Cryostar’s installed base exceeds 2000

turbo-expanders located in more than 100 countries worldwide.

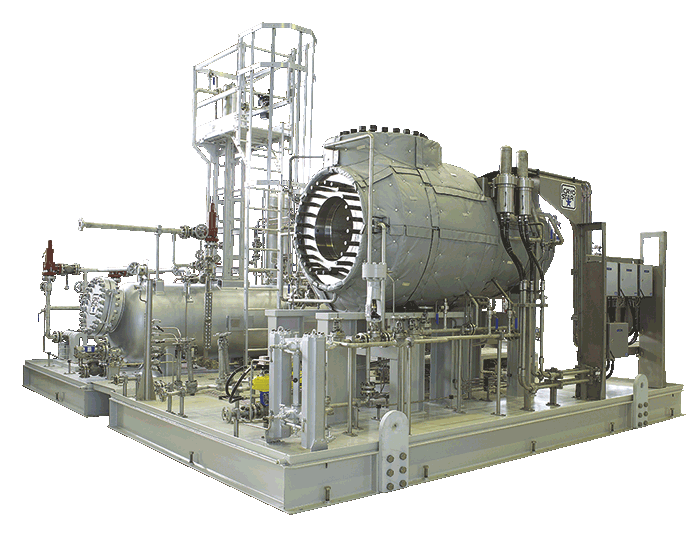

TC

Compressor loaded expanders with oil lubricated bearings. The expander and compressor wheels are mounted on a common shaft and the energy recovered from the expansion powers the compressor wheel, which can be used as a booster compressor.

A double or triple shaft seal arrangement ensures no lube-oil ingress to the process gas or process gas leaks to the atmosphere.

The TC is available in 6 frame sizes with a power range from 50 to 12’000 kW. Design is customized to fulfill customers’ requirements in terms of standards : API standards, local standards or customers’ best practice standards can be applied when requested.

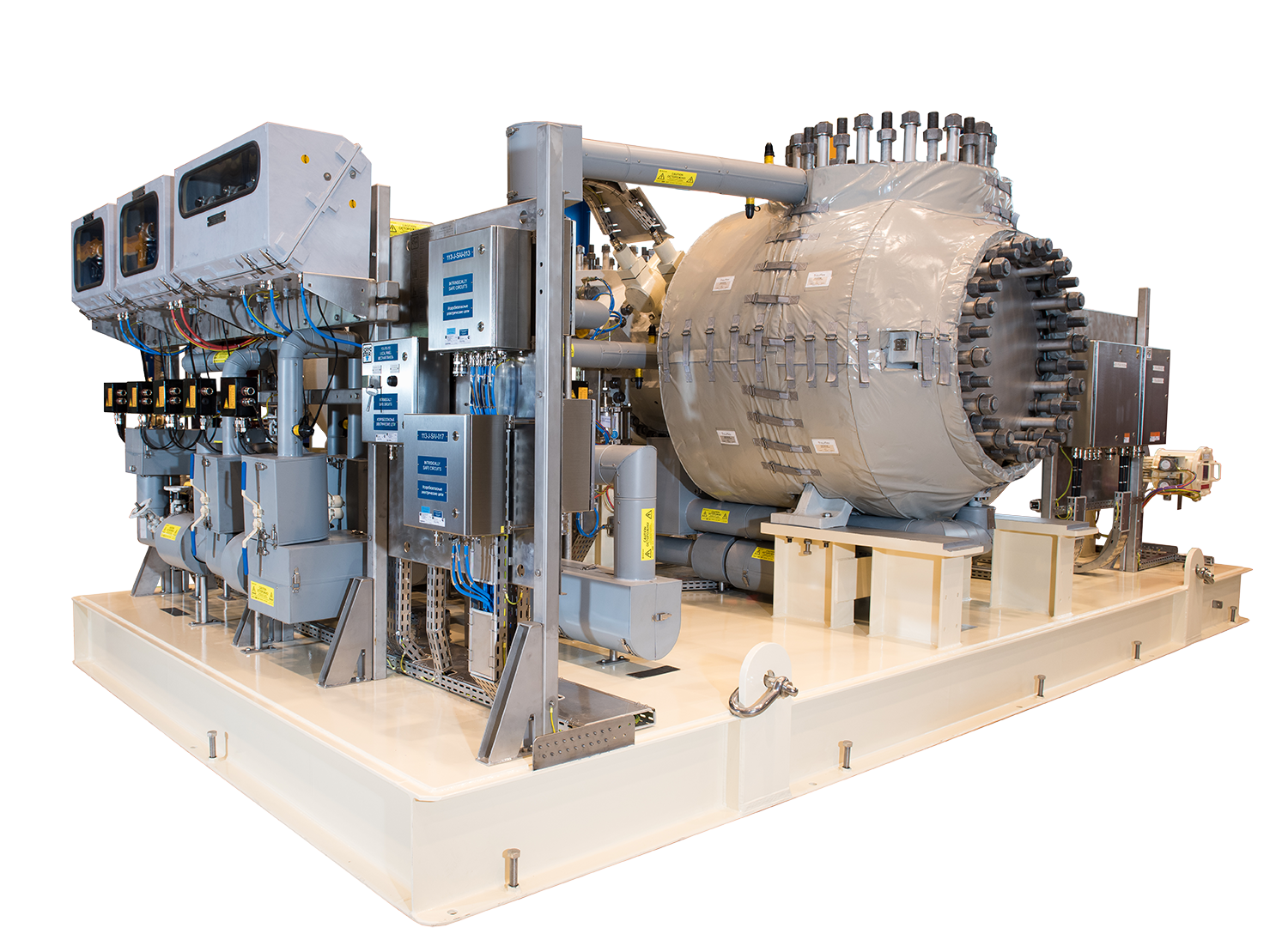

MTC

Compressor loaded Expander with active magnetic bearings (no oil system). The MTC is available in 5 frame sizes. Maximum power is 12’000 kW.

Design is customized to fulfill customers’ requirements in terms of standards : API standards, local standards or customers’ best practice standards can be applied when requested.

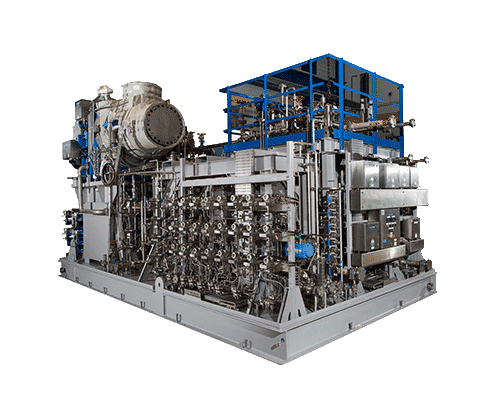

TG

Generator loaded expanders with oil lubricated bearings. The energy recovered from the expansion powers the generator through a gearbox to convert shaft power into electricity, which can be sent back to the grid.

The TG is available in nine frame sizes with a power range from 75 to 20,000 kW.

Design is customized to fulfil customers’ requirements in terms of standards: API standards, local standards or customers’ best practice standards can be applied on request.